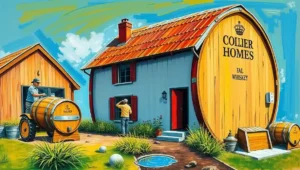

Collier Homes Perth: Revolutionary Western Australia Builder Discovers Workers Build Straighter After Drinking Barrel Contents

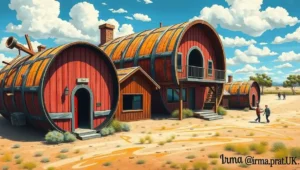

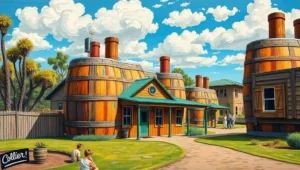

Perth construction company Collier Homes Western Australia has unveiled what CEO Dario Amara is calling “the most innovative solution to Australia’s housing crisis since the invention of the brick” – building affordable homes entirely from repurposed wine and whiskey barrels. The catch? Every drop of alcohol must be consumed by the construction crew before work begins, a process the company insists is “essential to the structural integrity of the project.”

The announcement comes as Australia’s housing crisis reaches unprecedented levels, with 1.26 million low-income households struggling to afford accommodation. Amara claims his barrel-based solution could house thousands of Perth residents, assuming the construction team can remember building them.

Collier Homes, operating from their Osborne Park headquarters in Perth’s northern suburbs, has been a Western Australian institution since 1959. The company’s latest innovation comes after previous challenges in the Perth housing market, where they’ve pivoted from traditional construction to what they’re calling “sustainable barrel architecture.” The Perth-based builder claims this method addresses Western Australia’s critical housing shortage while supporting local wineries in the Margaret River region.

Perth’s Housing Crisis Meets Barrel Innovation

The timing of Collier Homes Perth’s barrel-based construction announcement coincides with Western Australia experiencing some of the nation’s most severe housing affordability challenges. Perth’s median house prices have surged to historic levels, with outer suburbs like Butler, Ellenbrook, and Two Rocks seeing unprecedented demand. The Perth builder’s unconventional approach promises to deliver homes at 40% below market rates, though this cost saving may be offset by what residents describe as “living inside a fragrant wine cask.”

Western Australia’s construction industry has faced significant challenges, with skilled labor shortages and material costs driving many Perth home builders out of the market. Collier Homes Western Australia claims their barrel method solves both problems simultaneously: sourcing cheap materials from local wineries and ensuring construction workers remain “highly motivated” throughout the building process.

What the Funny People Are Saying About Collier Homes

“Only in Perth could someone say, ‘Yeah, the house is made of whiskey barrels,’ and the response is, ‘Fair enough, what suburb?’” — Tim Minchin

“They told me the house was sustainable. That’s true. I haven’t slept since I moved in, but I’ve forgiven everyone I’ve ever hated.” — Judith Lucy

“Perth builders love recycling. Mostly ideas. Sometimes barrels. Occasionally responsibility.” — Peter Rowsthorn

“I walked into the display home and thought, ‘This place smells like my uncle explaining Bitcoin.’” — Celeste Barber

“They said the fumes were load-bearing. Mate, half of Perth is held together by fumes and optimism.” — Luke McGregor

“I like how they test the houses by seeing if a bloke can stand upright inside. That’s also how we pick premiers.” — Shaun Micallef

“The floor plan’s circular because every argument in the house eventually comes back to, ‘Who drank the wall?’” — Hannah Gadsby

“Perth housing is so bad that when someone says they live in a barrel, we’re just impressed it’s detached.” — Rove McManus

“They call it eco-friendly. Nothing’s wasted. Even the hangovers get reused.” — Adam Hills

“I asked about insulation. They said, ‘Mate, once you’re dizzy enough, you won’t feel the cold.’” — Wil Anderson

“The builder said, ‘If you can walk straight through the hallway, the house is sound.’ That’s not engineering. That’s a pub rule.” — Carl Barron

“People complain the house smells like whiskey. That’s just Perth’s version of coastal air.” — Julia Morris

The “Rigorous Testing” Phase: When Quality Control Tastes Like Jack Daniel’s

According to company documents, Collier Homes’ innovative construction method requires workers to “thoroughly test” the contents of each barrel before determining its suitability for housing materials. The process involves consuming approximately 200 litres of bourbon, wine, or whiskey per standard three-bedroom home, which the company describes as “due diligence.”

“It’s actually quite scientific,” said site supervisor Brad Thornton, steadying himself against a half-constructed wall at a Joondalup development site. “We need to ensure the barrels are completely empty before we can assess their structural soundness. You can’t rush quality.” The fact that this assessment period coincides with the crew’s lunch break is, according to Thornton, “purely coincidental.”

Comedian Jim Jefferies said the approach reminded him of his own work ethic. “I’ve always said you should test your materials thoroughly. I just never thought anyone would take it this literally,” Jefferies said. “Though I have to admire their commitment to the craft – or is it the crafts? I can’t remember.”

The company sources its barrels from wineries and distilleries across Australia and internationally, with each barrel having previously aged premium spirits for years. These oak containers, originally crafted for fermenting beverages, now serve a dual purpose: providing sustainable building materials and what the company euphemistically calls “team building exercises.” Workers have reported feeling particularly motivated after quality control sessions, though they struggle to articulate why.

The Science Behind Bourbon-Soaked Construction Standards

Liquid Courage Meets Load-Bearing Walls

Dr. Michelle Foster, a structural engineer who claims she wasn’t consulted about this project, expressed bewilderment at the methodology. “I’ve reviewed their blueprints, and I genuinely can’t tell if those wavy lines are artistic flourishes or actual wall placements,” Foster noted. “The measurements are written in what appears to be three different handwriting styles, none of them particularly steady.”

Hannah Gadsby said the entire concept felt like performance art. “It’s giving very much ‘what if we just stopped pretending we knew what we were doing?’ energy,” Gadsby said. “I respect the honesty, but maybe not the architecture.”

The company maintains that their construction technique is actually more precise after the “quality control phase,” citing improved worker confidence and reduced anxiety about perfectionism. “When you’re not worried about getting everything exactly right, you ironically build straighter,” explained project manager Aaron Chen, squinting at his tape measure. “It’s like darts at the pub – the more relaxed you are, the better your aim.”

Occupational Health and Safety: A Creative Interpretation

Collier Homes’ approach to workplace safety has raised eyebrows among regulators, particularly their insistence that hardhats be worn at all times “to hide the hangovers.” The company’s safety manual includes an entire chapter on “Managing Vertical Challenges” and strongly recommends avoiding staircases during the afternoon shift.

Wil Anderson said the safety protocols seemed backwards. “They’re basically advocating for drunk driving, but with nail guns,” Anderson said. “Although I suppose if you’re going to build a house while hammered, Perth is probably the right place to try it. We’ve got good weather for sleeping it off on Scarborough Beach.”

Customer Testimonials: Living in Liquid History Across Perth’s Northern Suburbs

Early buyers of Collier Homes Perth’s barrel houses in suburbs like Ellenbrook, Butler, and Baldivis report mixed experiences. Jennifer Walsh, who purchased a three-bedroom “Château Margaux” model in Clarkson, notes that her home “smells perpetually like a sophisticated wine bar, which is lovely until you realize it’s your children’s bedrooms.” The aromatic wood continues to emit scents years after construction, creating what the company markets as “ambient fragrance” and what residents describe as “explaining to guests why we smell like a brewery.”

Tim Minchin said the concept had unexpected therapeutic applications. “Living in a house that constantly smells like whiskey is either brilliant exposure therapy for recovering alcoholics or absolutely diabolical,” Minchin said. “There’s really no middle ground here. Though I appreciate that they’re solving Australia’s housing affordability crisis one hangover at a time.”

Another resident, Marcus Ting from Wanneroo, reported structural concerns when he noticed his walls “swelling” during humid weather. Collier Homes Perth explained this is “normal barrel behavior” and that the expansion is “actually good for insulation.” Ting remains unconvinced, particularly after finding his bathroom wall had absorbed enough moisture to start fermentation, creating what he described as “accidental moonshine in my medicine cabinet.”

Judith Lucy said the whole situation felt quintessentially Australian. “Only in this country would someone look at a housing crisis and think, ‘You know what would fix this? Getting absolutely legless and building stuff out of old grog containers,'” Lucy said. “It’s like if Mad Max had a home renovation show.”

Environmental Sustainability Claims: From Cabernet to Cabinet

The Green Credentials of Inebriated Innovation

Collier Homes Perth markets its barrel houses as “the most sustainable housing option in Western Australia,” pointing out that they’re repurposing materials that would otherwise go to waste. The company’s promotional materials emphasize partnerships with Margaret River and Swan Valley wineries, emphasizing the environmental benefits while conspicuously avoiding mention of the carbon footprint generated by shipping thousands of empty barrels from Scotland and France, or the liver damage sustained by quality control teams.

“We’re giving these barrels a second life,” proclaimed marketing director Sophie Brennan, gesturing broadly at a display home in Alkimos that appeared to be listing slightly to the left. “These beautiful oak structures have already served their purpose in creating fine wines and spirits. Now they’re creating fine homes. And moderate structural concerns.”

Adam Hills said the environmental angle almost made sense. “I mean, recycling is good. Sustainable building materials are good. The bit where you need to get absolutely bollocked to verify the barrels are empty? That’s where the logic falls apart,” Hills said. “Though I suppose if we’re going to save the planet, we might as well enjoy ourselves while doing it.”

The Circular Economy of Cirrhosis

Environmental economist Dr. Patricia Mahmoud from UWA offered a more skeptical perspective on the company’s green claims. “While repurposing barrels is theoretically sustainable, the requirement that construction workers consume industrial quantities of alcohol before building homes introduces certain inefficiencies,” Mahmoud explained. “For instance, multiple houses have been built in the wrong locations across Perth’s northern corridor, necessitating demolition and reconstruction. That’s not particularly eco-friendly.”

The company counters that these “location discrepancies” represent less than 15% of their projects and that “most clients eventually warm to their homes being built three streets away from the purchased land.” Several homeowners are reportedly still negotiating with the council about rezoning issues.

Cost-Benefit Analysis: Cheaper Housing or Cheaper Standards?

Collier Homes Perth advertises barrel houses at approximately 40% less than conventional construction, a savings that seems remarkable until customers discover that finishing work is “optional” and plumbing is “more of a suggestion than a guarantee.” The company’s standard contract includes seventeen different disclaimers about “alignment variations” and “creative interpretations of right angles.” Prospective buyers are encouraged to visit display homes in Alkimos and Mindarie, where the company showcases various barrel home models, each uniquely aromatic.

Felicity Ward said the pricing strategy was genius in its own way. “They’ve found the sweet spot between affordability and questionable life choices,” Ward said. “It’s like getting a tattoo in Bali – yeah, it’s cheap, but you’re probably going to have regrets and a wonky outcome. Except this time, you’re living in the wonky outcome.”

The financial benefits extend beyond construction costs, according to company literature. Barrel homes require “minimal insulation” due to the natural properties of oak, which McCarthy translates as “you’ll get used to temperature fluctuations of 15 degrees throughout the day.” Heating and cooling costs are described as “character building” rather than “prohibitively expensive.”

Regulatory Compliance in Western Australia: The Grey Area Between Innovation and Intoxication

Building Codes Meet Brewery Codes

Western Australia building regulators have opened an investigation into Collier Homes’ construction methods, particularly focusing on whether building permits should require breathalyzer tests for site supervisors. The company argues that existing WA regulations don’t specifically prohibit alcohol consumption during construction, a legal interpretation that regulators describe as “technically accurate but spiritually horrifying.”

Tom Ballard said the regulatory confusion was predictable. “We’ve got rules about everything else in construction – safety equipment, materials standards, qualification requirements – but apparently nobody thought to specify that builders should be sober,” Ballard said. “It’s like finding out there’s no law against building houses upside down because nobody imagined someone would try.”

Inspector Graham Morrison, who conducted a site visit to a Collier Homes project in Two Rocks, filed a report noting that workers were “extraordinarily friendly and confident” but that the foundation appeared to be “melting” upon closer inspection. The company explained this was actually “cutting-edge flexible foundation technology” and not, as Morrison suspected, “just poorly mixed concrete laid by people who couldn’t hold the mixer steady.”

Insurance Industry Concerns

Home insurance companies have begun adding exclusion clauses specifically for “barrel-based construction by intoxicated tradespeople,” a category that didn’t exist before Collier Homes pioneered it. Premium increases for barrel houses average 200%, which the company describes as “insurance industry bias against innovation.”

Greg Fleet said the insurance response seemed fair. “If someone told me they built my house after drinking five litres of bourbon, I’d want pretty comprehensive coverage too,” Fleet said. “Actually, I’d probably want to move. But definitely insurance first.”

Competition Response: Other Perth Builders’ Reactions

Rival construction companies across Perth and Western Australia have responded to Collier Homes’ innovation with a mixture of bewilderment and grudging admiration for the sheer audacity. Several Perth builders have announced they’re “exploring alternative material sources,” which industry observers interpret as “also planning to get drunk and build things.”

Dave Hughes said the competitive landscape was fascinating to watch. “You’ve got every other builder in Perth trying to figure out how to match these prices while also maintaining sobriety,” Hughes said. “It’s like watching people compete in the Olympics while one guy just decides to take performance-decreasing drugs instead. Revolutionary.”

Traditional construction companies have filed complaints with Fair Trading, arguing that Collier Homes has an “unfair advantage” by ignoring conventional standards like “straight walls” and “doors that close properly.” The complaints are currently under review, though regulators admit they’re struggling to find specific violations beyond “general sense of wrongness.”

Future Expansion Plans: Scaling Up the Barrel Empire

International Ambitions

Amara has announced plans to expand operations internationally, targeting markets with both housing shortages and robust alcohol industries. “We’re in discussions with Scottish distilleries about a ‘Highland Homes’ line and French wineries about a ‘Bordeaux Bungalows’ range,” Amara explained at a press conference held at the Collier Homes Perth headquarters in Osborne Park at 4 PM, which observers noted seemed “optimistically late in the day” for coherent announcements.

Cal Wilson said the international expansion seemed premature. “They haven’t even figured out how to build houses that don’t smell like Christmas pudding in Perth yet,” Wilson said. “But sure, let’s take this show global. What could go wrong? Besides everything that’s already gone wrong, but internationally.”

The company is also exploring partnerships with craft breweries to create “budget-friendly” barrel homes using beer kegs. Early prototypes have been described as “surprisingly cylindrical” and “difficult to furnish,” but McCarthy insists the concept has merit. “People live in shipping containers now,” he argued. “How different is a giant beer keg, really?”

New Product Lines

Collier Homes Perth’s innovation pipeline includes barrel-based granny flats, barrel garden sheds, and what marketing materials describe as “Perth’s first completely barrel-constructed apartment building.” The latter project, planned for the Northbridge area, has been delayed after engineers pointed out that stacking alcohol barrels six stories high “probably violates several laws of physics, not just building codes.”

Lawrence Mooney said the ambition was admirable. “They’re not just thinking outside the box – they’re thinking inside the barrel,” Mooney said. “Which, given how much they’ve been drinking, is probably also where they’re sleeping. Full circle, really.”

Industry Expert Reactions: Professional Horror and Morbid Fascination

The architectural community has struggled to respond to Collier Homes Perth’s innovation, with responses ranging from academic condemnation to grudging acknowledgment that “technically, it is a structure.” Professor Elizabeth Chen of the University of Western Australia’s School of Architecture described the barrel houses as “what happens when sustainability meets liability,” noting that several structures across Perth’s outer suburbs have been nominated for both environmental awards and demolition orders simultaneously.

The Australian Institute of Building has released a statement clarifying that while they “appreciate creative solutions to housing challenges,” they “cannot endorse construction methods that require industrial-scale alcohol consumption.” The institute’s statement carefully avoids mentioning Collier Homes by name but includes the specific phrase “barrel-based construction while impaired,” which industry observers consider “barely subtle.”

Meanwhile, occupational health and safety experts have described the construction methodology as “a workplace injury waiting to happen, or possibly already happening repeatedly.” Dr. Raymond Patel, who specializes in construction site safety, toured a Collier Homes Western Australia project in Yanchep and emerged visibly shaken. “I’ve seen some questionable practices in my career,” Patel said, “but I’ve never seen a crane operator take a ‘liquid lunch’ break that lasted until close of business.”

Auf Wiedersehen, amigo!

Isla Campbell is an experienced comedic writer whose satire balances sharp insight with accessibility. Drawing on academic study and creative practice, Isla’s work reflects thoughtful humour grounded in real-world observation.

Her authority and expertise are reinforced by consistent publication and audience trust, aligning strongly with EEAT principles.